Smart Warehouse Overview

A smart warehouse supports OpEx, CapEx, and the advantages of the digital transformation taking place. This includes hardware, software, and automating your warehousing operational flow.

What is a Smart Warehouse

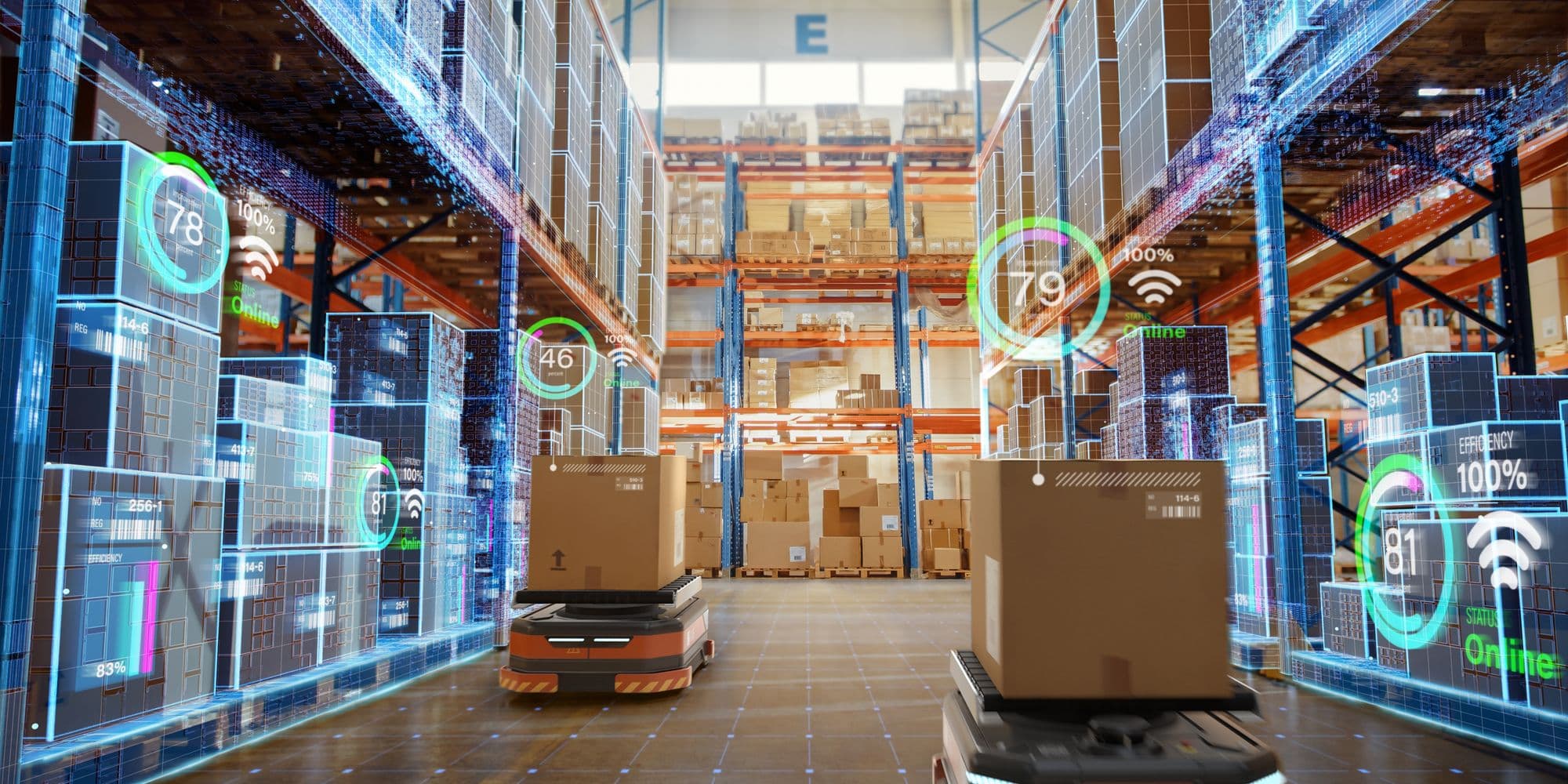

In a manual warehouse, people moved around with spreadsheets, lists, and stacks of printed purchase documentation. This includes manually picking products, juggling inventory levels, and loading products in or out of the shipping dock. With a smart warehouse, inventory and orders in sync with all transactions recorded along the way for perfect visibility. Instead of a pen and pencil for tracking, workers simply harness IoT (Internet of Things) technology to scan each product. Management can watch the flow happening in real-time from their connected business systems or centralized database of record. Workers aren't having to scrounge for products, but rather move in a pragmatic pattern with perfect visibility. In some cases, robots, robot carts, and automated machinery assist with some of that flow as well - again leveraging the accurate data flowing in and out of ERP, Finance, WMS, BSS, and OSS systems.

Similar to a smart home, where the house connects smartly, and functioning with perfect productivity and pragmatic movement. A smart warehouse is much the same, empowered by automated and interconnected technologies. It is overlaid against business operations best practices and known processes. These technologies work together to increase productivity and efficiency throughout the warehouse. Ultimately minimizing the need for excessive human power while decreasing errors significantly.

Benefits of Smart Warehousing

Smart warehouse systems have the right amount of inventory on hand and the visibility to that inventory. It is a process-based ecosystem where various interconnected warehousing technologies work together. Inventory is received, sorted, organized, and pulled for shipment with all transactions recorded. The most extensive smart warehouse solutions digitize the entire operation. This may even include suppliers, vendors, and consultants to get an even broader picture.

Warehousing operations are becoming more complex with the shift from JIT (Just In Time) to JIC (Just In Case). To meet these evolving needs, smart warehouses need to dynamically adjust to the ebb and flow of inventory management.

Staffing optimization is a direct benefit of smart warehousing, limiting the need for warehouse staff and planning for busy periods. Smart warehousing works with numerous platforms through APIs and Integrations, in both a push and pull symbiotic way. "Push" means collecting the information from each transaction, reconciling the data, and sending that information to connected business systems. "Pull" is retrieving all known inventory information from systems like ERPs after they have added the new transactional data. It's a perfect back and forth sharing that literally gives everyone in the organization visibility across the board.

The general visibility of critical corporate asset data has become mandatory for software used by the various supply chain functions. Smart warehousing allows users to find what they want immediately, thanks to having reconciled data flowing throughout the company. This river of data gives managers an omniscient view of the entire warehouse system, and how its various sections and departments are performing. If inaccuracies in inventory appear, everyone will immediately know where and when to quickly solve the discrepancy. This way smart warehouse and supply chain management can proactively address issues before big problems can arise.

Example of a Smart Warehouse

An example of IoT in a smart warehouse management system begins when a warehouse receives inventory. As the shipment comes in, workers scan barcodes using hardware or phones to kick off the item in the system. That same item is then scanned at every possible point -audits, movement, deployment, repair, etc. All of this happens "automagically" and seamlessly, so nothing falls between the cracks, and every possible aspect of asset data is known. Without IoT scans, or RFID scans, employees must complete each step in the process manually, which is prone to error, theft, fraud, over-stocking, under-stocking, and outages.

In the (very) immediate future, warehouse automation will become even more prevalent, and smart warehouse systems will be a key competitive advantage. It's time to start implementing automation, and we can help. From field data collection hardware and software to data reconciliation and business system integration - we can bring you the superhighway of asset data. Check out Sitehound now.

Find a complete guide to warehouse management here.